FOOD FRIENDLY® grinding burrs: coffee best friends

Always focusing on market requirements, for Nuova Ricambi is very important to guarantee an high quality standard for all our customers. We propose ourselves as a reference point for all coffee machine builders, technicians, roasters and those who work daily in the world of coffee. That’s why we chose to add to our catalogue a quality product as the FOOD FRIENDLY® grinding burrs.

The FOOD FRIENDLY® burrs allow excellent coffee grinding, thanks to the special technology employed to manufacture them. The grinders in this range are an innovative product and, compared with standard burrs, they perform the most precise and uniform work, for the same amount of ground coffee.

The basic criterions for chosing FOOD FRIENDLY® grinding burrs are:

- Reliability: They do not undergo deformations, thanks to the particular heat treatment they have been subjected; moreover, they settle right after the first grinding, and so you don’t need to grind a lot of coffee during the first setup.

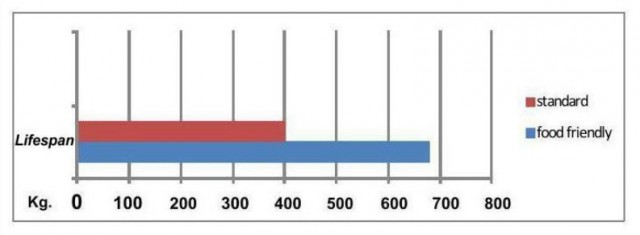

- Lifespan: These grinding burrs are realized with a special steel and they undergo particular processing and heat treatments wich ensure a longer life of 70% compared to standard grinding burrs produced in steel 18NiCrMo5, hardened and tempered in atmosphere.

-

- Less contamination: They have been expressly created, and also certified, so that the ground coffee has only a minimal contamination coming from the detachment of surface residuals of metal parts.

In traditional machines, indeed, it often occurs an unexpected oxidation strip, that tends to remove itself very easily causing unavoidable contamination of ground coffee.

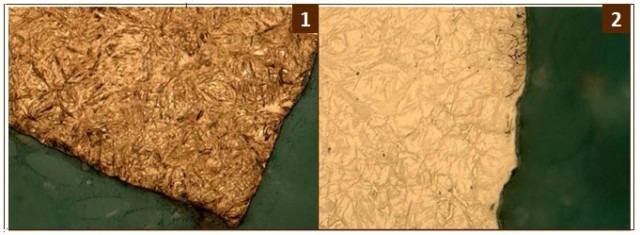

In the two images above, thanks to the contrast provided with the aid of a metallographic technique, it is possible to see the microstructure of the grinders.

In the first image (Picture 1) we can see the martensite microstructure of the FOOD FRIENDLY® grinding blades, which is free from layers with abnormal oxidization, and less subjected to wear and tear and contamination.

In the second one (Picture 2) we can see the microstructure of the standard grinding burrs that indicates the presence of a surface layer with abnormal oxidization.

The presence of surface layers with a lower level of hardness than the underlying material causes lower resistance to repeated stress than the resistance achieved during the manufacturing and treatment processes for FOOD FRIENDLY® grinding blades. So, considering same loads, traditional burrs have lower performance than FOOD FRIENDLY® ones.

Nuova Ricambi Team suggests FOOD FRIENDLY® burrs because, beyond being certified, they respect coffee keeping its original features after each grinding process too.